Product Prototype Development Services

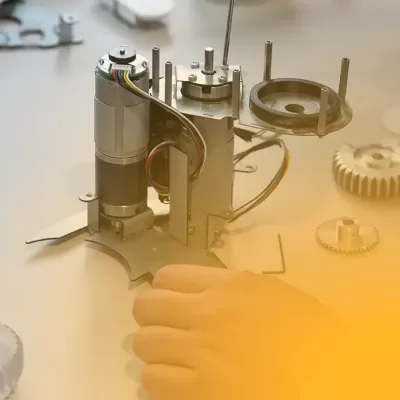

Our in-house model-making and prototype machining can produce photorealistic models, complex engineering prototypes, and high-tolerance machined parts.

Our 3D printing and laser cutting services allow for quick-turn prototypes. In our engineering laboratory, we have the tools necessary to build and test multifunctional electromechanical systems. Building engineering check models helps validate the products we engineer before we deliver the project — this all but guarantees your ROI.

Why Us?

- Iterative prototypes across all stages of development

- High-quality visual models

- Quick turnaround times to accelerate your process

- Transparent and effective communication

From Idea To Execution

Walking you through the entire product development journey

Prototype engineering

Fabricate and test early-stage physical and functional models to evaluate functionality, performance, and feasibility before full-scale production

Our Process

Define Product Requirements

Requirements are defined early in the process, whether for structural or performance needs, aesthetic goals, COGS targets, etc. We can assist in defining the product requirements document if needed.

Product Architecture

The design concepts are reviewed for engineering feasibility or concerns.

Mechanical Concept

Industrial design concepts are then reviewed for manufacturing details like molding and assembly while addressing structural, thermal, or other high-performance requirements.

Safety & Compliance

Compliance needs, including EMI shielding, material compliance, UL, FCC, TUV, etc., are taken into account.

Design for Manufacturing

Whether it’s plastics or metals, reviews will occur with the appropriate manufacturers to ensure all specifications can be met. Any cost drivers or challenges will be reviewed, and an action plan will be created.

Mechanism Testing & Iteration

Complex mechanisms are tested early and often. Quick iterations using our in-house 3D printing or laser cutting are made for testing before moving to higher-fidelity prototypes.

EEngineering

Solve advanced engineering problems to create innovative product solutions and get your product to market.

- Mechanical engineering

- Process & material knowledge

- Design for manufacturability

- Tooling management

- Finite element analysis (FEA)- static and dynamic

- QC drawings- GD&T

- Design for safety compliance

- Safety certification submission support

- Testing protocol can be provided if appropriate

Featured Work

Blogs

Engineering

Mesh modeling in industrial design

Engineering

Solving the hurdle of plastics in product design

Engineering