Mesh modeling in industrial design

Why are we lagging behind? Polygonal modeling is the most widespread and versatile 3D modeling technique, used in videogames and character design, advertising, movies, VR, etc. The expressive potential and usability of this technique make it necessary when modeling physical products. So why aren’t we seeing it everywhere? Of course, the precision and control you [...]

Why are we lagging behind?

Polygonal modeling is the most widespread and versatile 3D modeling technique, used in videogames and character design, advertising, movies, VR, etc. The expressive potential and usability of this technique make it necessary when modeling physical products.

So why aren’t we seeing it everywhere?

Of course, the precision and control you get with parametric surfaces is much higher, but I think that large organisations continue to use the same software that their employees already master (it is a legacy system) and resist change. Smaller studios use Rhino, which is the most versatile and convenient 3D software. Until recently, it did not offer subdivision surface modeling.

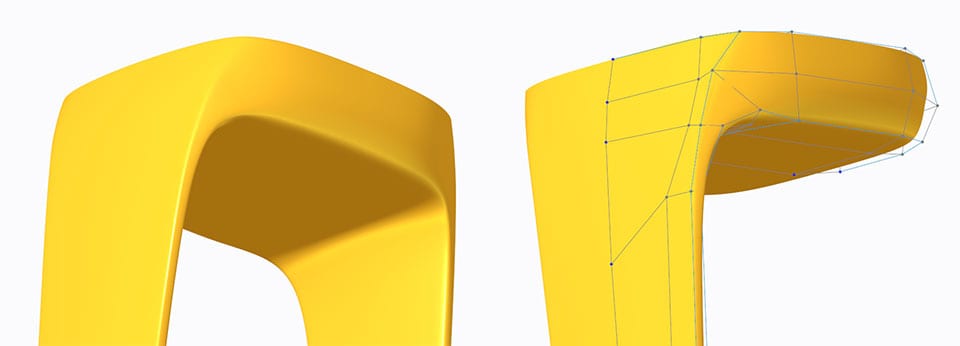

Parametric surfaces, which I call NURBS (Non-Uniform Rational B-spline), are the surface-generating “language” on which Rhinoceros 3D is based, ideal for modeling automotive-style aerodynamic shapes.

Designers who doesn’t work full time in the automotive industry struggle to create the shapes they want, or at least, these shapes don’t come out so easily. It’s not a lack of imagination, will, or ability.

It’s as if the program decides what you can and cannot do, while outside the industrial design world, professionals continue to produce great models and renders at a impressive rate, thanks to software like Zbrush, Maya, Blender, to name a few, with the tools and user interface which are 20 years head start.

T-splines tried to bridge this gap by offering a plugin for Rhino, recently integrated in Autodesk Fusion360, while Creo Parametric offers freestyle, a great way to import and edit a lo-poly mesh into a parametric software. Until now, these programs had a limited number of functions, and it seemed difficult for a nurbs based software to catch up with the giants dominating the gaming industry.

I think industrial designers should integrate organic modeling features alongside the classic parametric tool. Not just to “explore” new shapes, as advertised by some software houses, even though that is a great step forward.

Subdivision surfaces and the advanced modeling interface you see in softwares used in the gaming industry should be merged seamlessly into the industrial design workflow, because the advantage to create gorgeous shapes is great, and most of all, it shouldn’t be painful.

Working for the toy industry in the last 4 years I just sculpted meshes on Zbrush and imported the obj on my favourite parametric softwares. Could Rhino 7 solve the problem? I’m looking forward to see if it delivers.